Research

We give our priority on customer satisfaction with strictly high-quality through constant development of technologies

- R&D

- R&D Operation

- R&D Test Room

- Invention

- Bio Plastic

- Eco-Friendly Headliner

- VOCs/Odor Reduction

- Anti-bacterial

- CFRP

- Root Company Certification

- Test Equipments

- Patent

R & D

R & D Root Company Certification

Root Company CertificationRoot Company Certification

Root Technology

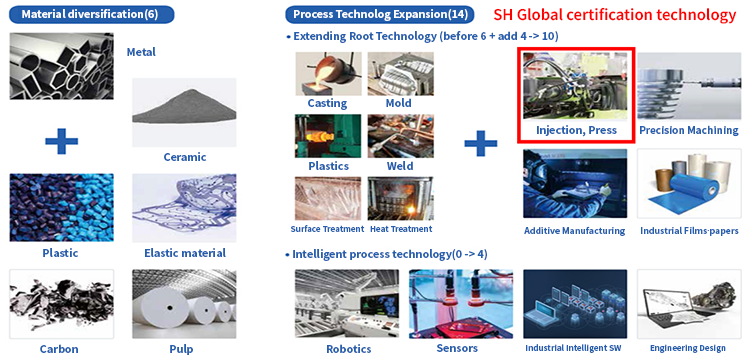

Root technologies are basic process technologies utilized across the manufacturing industry and next-generation process

technologies that are key to the future growth of the manufacturing industry, such as injection and presses, precision machined rods, and sensors.

※ Root Industry : Naming in the sense that, like the roots of a tree, they are not visible on the surface but are embedded in the final product and form the basis of manufacturing competitiveness.

Diversification of materials and expansion of root process technolog

Add 'next generation process technology' such as injection press, precision processing, robot, and sensor for intelligentization and material diversification (metal → plastic, ceramic, etc.) to six 'base process technologies' related to existing metal materials such as casting and molds

| Section | Before | After | ||

|---|---|---|---|---|

| Material diversification | 1 | Metal | 5 | Ceramics, Plastics, Elastomers, Carbon, Pulp |

| Process Technolog Expansion | 6 | Casting, Molds, Plastics Welding, Surface Treatment Heat Treatment | 4 | Injection · Press, Precision Machining, Additive Manufacturing, Industrial Films · papers |

| 4 | Robotics, Sensors, Industrial Intelligent SW, Engineering Design |

* Future growth technologies for manufacturing considering industry trends such as material technology convergence and diversification

Issued by

KITECH(Korea Institute of Industrial Technology)

DONG KWANG TECH

SH-BP

SH-INT